Significance and Test Method

Hardness is the mechanical resistance of a material to penetration by a solid body. It is one of the most frequently tested properties of elastomer materials.

Significance for application technology

Hardness provides information about the deformation behaviour of materials. If it is determined on standard specimens, it allows, together with other material characteristics, to identify formulations. Together with the measurement of density and component dimensions, hardness measuring is one of the three most important parts of an identity verification. It is therefore often carried out as part of an incoming goods inspection.

The Hardness Test

There are different test methods to measure the hardness of a material. The selection of the appropriate measuring method depends primarily on the type of material and the geometry of the test specimen and is also determined by the degree of hardness to be expected.

For hardness testing of elastomers and thermoplastic elastomers, depending on the basic hardness and geometry of the test specimen, the hardness measurement methods in accordance with Shore and IRHD are predominantly used. Therefore, we at Elastomer Institut Richter test exclusively using these methods.

Hardness in accordance with Shore A and Shore D

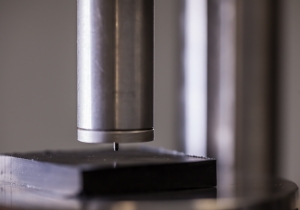

Shore hardness measurements in accordance with DIN EN ISO 868, DIN ISO 7619-1 and ASTM D2240-00 are intended as material parameters for measurement on plane-parallel standard specimens.

Shore hardness measurements in accordance with DIN EN ISO 868, DIN ISO 7619-1 and ASTM D2240-00 are intended as material parameters for measurement on plane-parallel standard specimens.

A test on elastomer components depends on the geometry and is often used, even if the result is the “apparent” hardness and this must be specified beyond the standard hardness or agreed with the supplier. The Shore A ( frequently used) and Shore D (rather rarely used) measuring methods differ in the geometry of the indenter and the hardness range they cover.

The Shore A indenter has the shape of a truncated cone. With it, hardnesses from 10 to 90 Shore can be measured. For harder materials above 90, the Shore D indenter, a truncated cone, should be used.

IRHD Ball Indentation Hardness

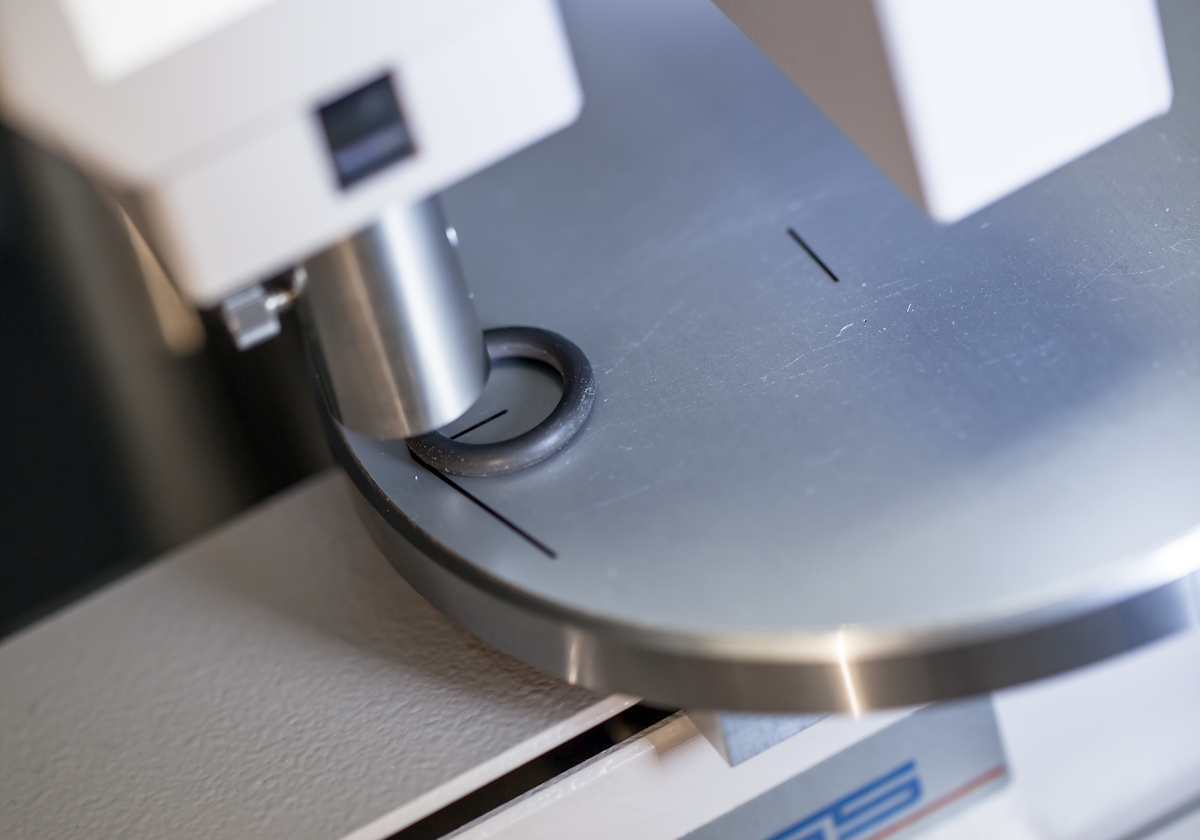

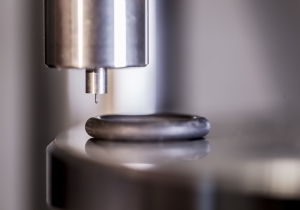

The measuring methods of the IRHD hardness in accordance with (DIN) ISO 48-2 or also ASTM D 1415 are suitable for standard test specimens as well as for finished parts. However, this should be specified and agreed with the supplier. The indenters are ball-shaped and differ in diameter depending on the method. The IRHD methods are designated as M, H, N or L. The microhardness method, IRHD M, is usually used to determine the hardness of small elastomer components. Other methods are hardly ever used.

The measuring methods of the IRHD hardness in accordance with (DIN) ISO 48-2 or also ASTM D 1415 are suitable for standard test specimens as well as for finished parts. However, this should be specified and agreed with the supplier. The indenters are ball-shaped and differ in diameter depending on the method. The IRHD methods are designated as M, H, N or L. The microhardness method, IRHD M, is usually used to determine the hardness of small elastomer components. Other methods are hardly ever used.

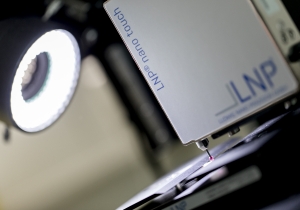

IRHD Universal Hardness with the LNP Micro Indenter

The micro indenter LNP works with highly sensitive force and displacement measurement and almost arbitrarily small indenters. This makes it possible to measure the IRHD hardness reproducibly in accordance with ISO 48-2, method M, on almost all finished parts and test plates. This promising measuring method (see also: lnp-northeim.de) is used by us with great success in damage analysis and quality assurance.

The micro indenter LNP works with highly sensitive force and displacement measurement and almost arbitrarily small indenters. This makes it possible to measure the IRHD hardness reproducibly in accordance with ISO 48-2, method M, on almost all finished parts and test plates. This promising measuring method (see also: lnp-northeim.de) is used by us with great success in damage analysis and quality assurance.

Further Hardness Testing Methods

Besides Shore and IRHD, other hardness testing methods are known in the context of plastics testing. For example, the hardness of glass fibre reinforced plastics, thermoplastics or thermosets is also determined according to Barcol. In addition, Rockwell or Vickers are also used in some cases.

In our testing laboratory, we exclusively use the methods in accordance with Shore and IRHD-M and LNP microindenters due to the products, materials and fields of application that we encounter on a daily basis.

Downloads

You can find further and more detailed information on the different hardness testing methods and the significance of hardness as a material parameter in our technical reports:

Hardness Test

In the report you will find answers to the following questions: How and with which methods is the hardness tested on elastomer components? Can the results of hardness measurements be compared or converted to other testing methods? Which conclusions can be drawn from the hardness test regarding the quality of a material or component?

100 Years Shore A

A historical review on the development and research of the Shore A measurement method with reference to today’s testing practice.

IIdentity verification for elastomers - hardness and density

Within the scope of an identity verification, certain material properties are examined on components of a test lot and checked for conformity with the reference values from the sampling. On elastomer components, the density and hardness of the component material are usually determined in addition to the dimensions.

Special edition of the professional journal DICHT!

In the DICHT! special edition O-Ring Prüflabor Richter you will find a comprehensive overview of common tests and analysis methods in elastomer technology. Discover the collected knowledge about elastomer testing in this issue.