Significance and Test Method

Ozone is a colourless and toxic trace gas and, as ozone layer in our atmosphere, protects us from the sun’s harmful UV radiation. It consists of three oxygen atoms and is highly reactive. The chemical formula is O3.

Close to the ground, ozone results from complex photochemical processes and, in sufficient concentrations, damages not only the health of living creatures but also plants and materials.

Highly unsaturated polymers, especially NBR, NR and SBR, are particularly vulnerable. The double bonds of the polymer main chain contained in the unsaturated elastomers are crucial. These can easily break down due to the ozone gas and react with the oxygen atoms of the ozone. Even an ozone concentration typical for the environment leads to the so-called ozone cracks when the components are subjected to additional stress. These are deep cracks vertical to the direction of stress.

Significance for Application Technology

In practice, ozone cracks occur particularly on pre-assembled, that is, stretched NBR seals that are exposed to the environment without protection. The typical damage to the components already occurs at an elongation of 3-5% and contact with ozone-containing air in free exchange.

Ozone-protected elastomers contain ozone protection agents, for example antioxidants and ozone protection waxes, which as “pawn sacrifices” react primarily with the surrounding ozone or are washed off. Depending on the ozone concentration, this protection lasts only for a limited time, which depends on the application conditions.

Ozone tests provide information about the ozone resistance of materials and help to evaluate the effectiveness of the ozone protection used.

The Ozone Test

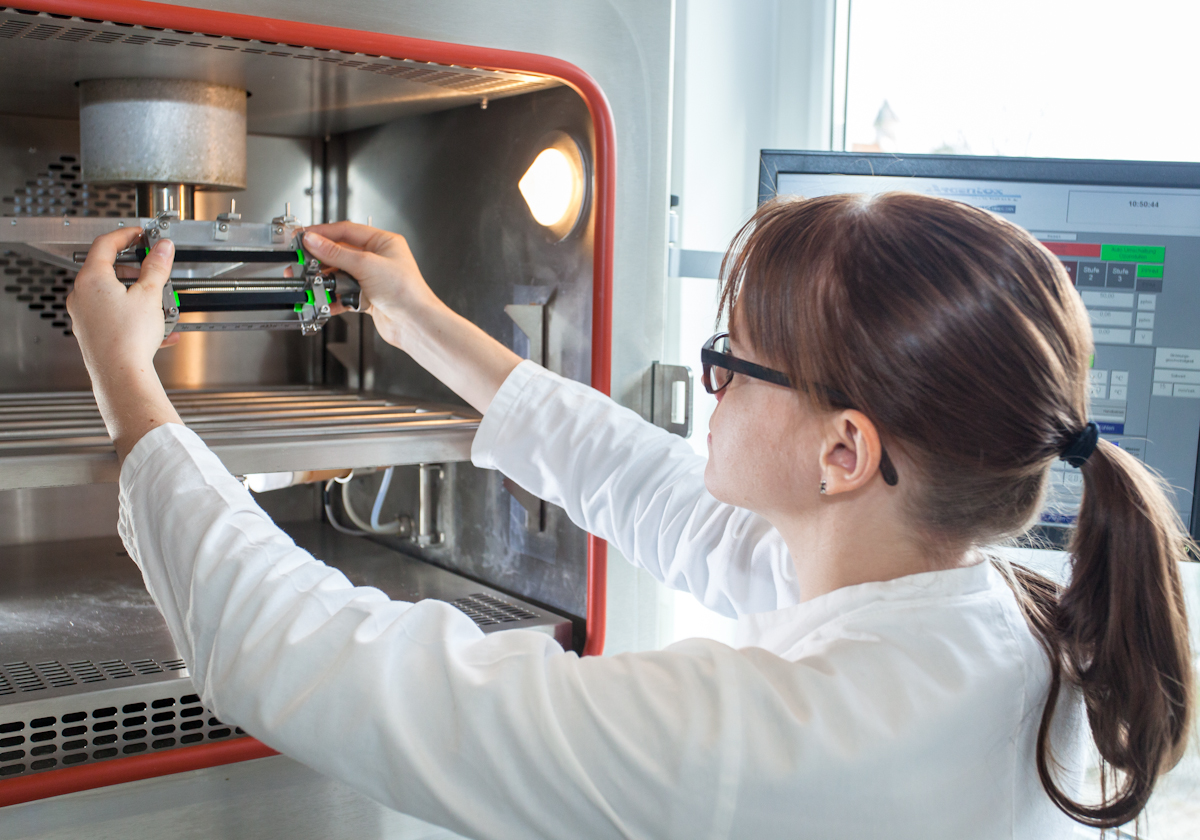

(DIN) ISO 1431 describes methods for determining the resistance of elastomers or thermoplastic elastomers to ozone cracking. It replaces the well-known DIN 53509 and describes static and dynamic tests. DIN EN ISO 7326 defines different test methods for the examination of hoses.

During the test for ozone resistance, the material samples are stretched as specified and exposed to a defined ozone concentration for a fixed, limited time. After the test, we examine the samples for cracks.

Downloads

You can find more information on the damage pattern of ozone cracks in our technical reports:

Ozone cracks on elastomer seals and materials (long version)

In this article you will find background information on the failure mode of ozone cracks and learn how to distinguish this damage from others on the component. We provide information about testing possibilities and give tips on to prevent ozone cracks in practice.

Ozone cracks on elastomer seals and materials (short version)

In this article you will find background information on the failure mode of ozone cracks and learn how to distinguish this damage from others on the component. We provide information about testing possibilities and give tips on to prevent ozone cracks in practice.