Significance and Test Method

The tensile strength of a material is the maximum mechanical tension it can withstand before it cracks. It is given in N/mm² or MPa.

The tear resistance of a material, also called tensile strength at break, is the mechanical tensile stress at the exact moment of tearing and is also given in N/mm² or MPa.

Since the maximum tensile stress and the tensile stress at the moment of rupture are usually identical for elastomers, the two terms are often used synonymously.

Elongation at break is a characteristic value that describes the maximum percentage elongation that a tensile specimen experiences at the moment of break. It therefore describes the deformability of a material under tensile load.

Significance for Application Technology

All three characteristic values are determined in the tensile test and provide information about the mechanical load capacity of a material.

The Tensile Test

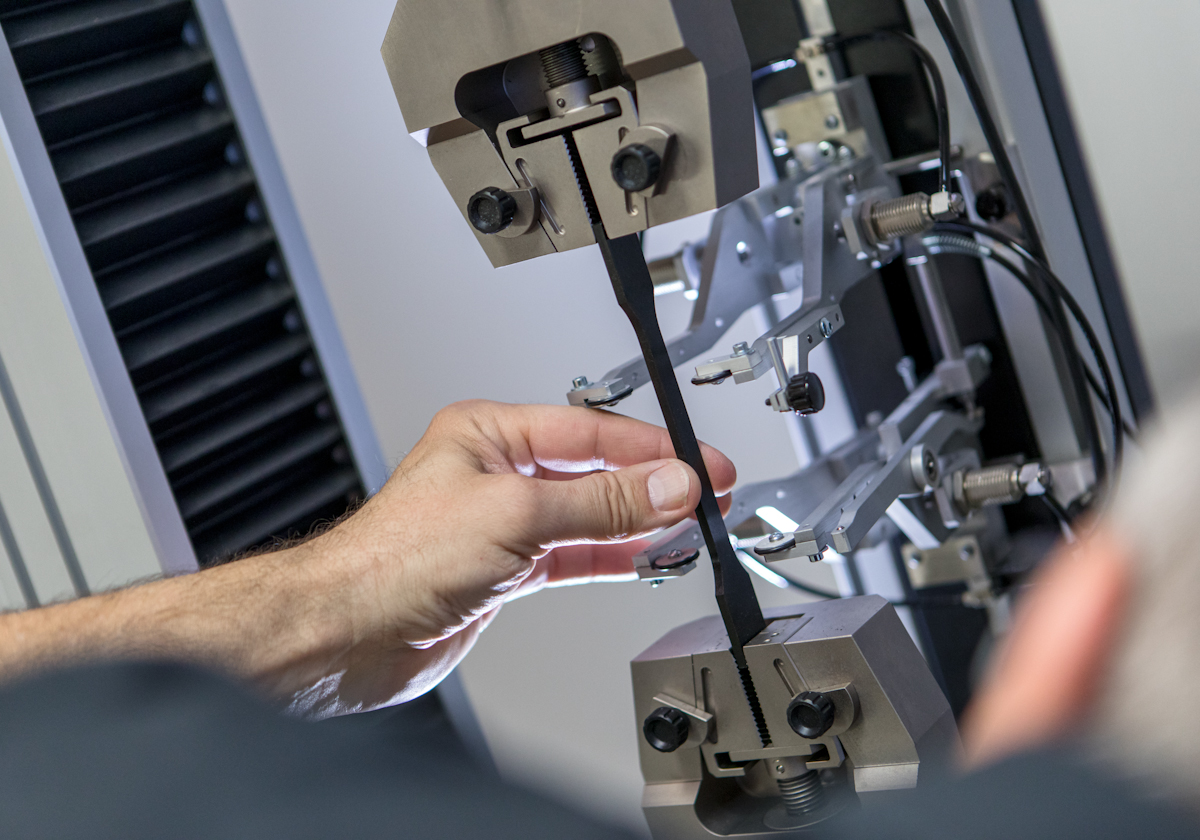

The tensile test is described in the standards DIN 53504, ISO 37, VDA 675 205, ASTM D412 and ASTM D1414. We work in our test laboratory mainly in accordance with DIN and ISO. During the tensile test, standardised test specimens, in most cases so-called shoulder bars, are clamped in a tensile testing machine and stretched at a constant feed rate until they break. The gradient of the required force and the strain is recorded and shown in a tensile strain diagram.

Downloads

You can find more detailed information on tensile strength, tear resistance, elongation at break and tensile tests in our technical reports:

The tensile test - Fundamentals of testing technology and its practical application

The report describes the procedure of tensile tests and shows the significance of the results with regard to the mechanical capacity and processing quality of materials. In addition, the report describes important test standards and test specimens. It explains the characteristic values of tensile strength, tear resistance and elongation at break, which are determined via the tensile test, and shows external influencing variables on these characteristic values and the results of the test.

The Tensile Test on Rings - Basics of Testing Technology and Important Facts to Know

The report describes the tensile test on rings and explains the sense of tensile tests on prefabricated parts. You will learn more about the influences of size, geometry and condition of the components as well as test equipment and test procedure on the determined test results.