Components

Seals • Engineered Rubber Parts • Hoses • Automotive Parts

With 25 years of experience in elastomer technology, countless cases of failures analysed, material analyses, seminars and consultations, today the “Elastomer Institut Richter” is on your side for the testing, assessment and qualification of all engineered rubber and thermoplastic components with word and deed and our extensively equipped testing laboratory.

We are rooted in sealing technology. Elastomer seals and their applications are therefore one of our most important fields of activity. Wherever rubber products seal against liquid or gaseous substances, we support you with our expertise.

We specialise in elastomers and thermoplastic elastomers. In addition, our expertise also extends to some thermoplastics, such as polyamide and PTFE. We are familiar with these material groups, advise you on their application and suitable tests and qualify materials for your application.

Sealing Elements

We deal with numerous different sealing elements as part of our daily work. In addition to standard seals such as the O-ring, historically one of the most common seals in our laboratory, we work with static and dynamic seals, rotary seals and moulded parts:

O-ring, rotary shaft seal, flat seal, lip seal, X-ring, Quad®-Ring, gasket, rubber-metal seal, rotary seal, rectangular ring (Kantseal), face seal, silicone seal, LSR (liquid silicone rubber) seal, wiper, polyurethane seal, ball seal, diaphragm, flange seal, grooved seal, valve seal, custom moulded parts and many more

Testing and Consulting

Right from the beginning of a product’s development, we answer your questions about the basic properties of selected elastomer compounds, test the behaviour of the sealing materials in heat, cold or relevant media and check the ageing resistance of the materials.

In addition, we use our many years of experience to assess the long-term behaviour of sealing elements and to estimate service life, thus helping you to do long-term planning for new projects and to optimize the performance of your products.

With the help of our state-of-the-art analytics, we are also able to determine polymers and ingredients, evaluate complete formulations and identify any changes.

Failure analysis of seals is one of our specialities. We investigate possible returns and defects for you, provide you with comprehensive support in identifying the root cause and help you to avoid further cases of failure.

The Standard Component O-Ring

For O-rings, the Elastomer Institut Richter offers conformity tests in accordance with ISO 3601-5, Table 2 and for elastomer formulations in accordance with Tables 3 to 9. We test on test plates as well as on O-rings.

For more information on the standard seal O-ring, see our technical report:

With the new ISO 3601, Part 5 (O-ring materials), the O-ring has finally become a standard part. Whereas previously only the dimensions (Part 1) and the permissible surface deviations (Part 3) were standardised, the new edition of the international standard also contains specifications for the formulation and the degree of vulcanisation of O-rings (hardness and compression set). This report explains the individual parts of this O-ring standard and, in particular, shows why the new Part 5 is important for users.

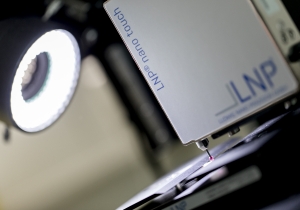

Micro Seals and Filigree Structures

With our special LNP® measuring technology, we are able to mechanically test even the smallest seals. Even with very filigree structures and composite parts, in most cases it is possible with the new measuring technology to reliably determine the micro-hardness of the material and the degree of cross-linking directly at the seal.

With our special LNP® measuring technology, we are able to mechanically test even the smallest seals. Even with very filigree structures and composite parts, in most cases it is possible with the new measuring technology to reliably determine the micro-hardness of the material and the degree of cross-linking directly at the seal.

Since the foundation of the O-Ring-Test-Laboratory Richter in 1996, we have grown out of sealings and have evolved from a pure O-Ring test laboratory to a well-respected Elastomer Institute. Meanwhile, we deal with a large variety of engineered rubber products and materials.

Engineered Rubber Parts - The Products

The products we examine for our customers are as varied as the possible uses of elastomers in industrial applications. In addition to elastomer moulded parts, these also include rubber-metal or elastomer-plastic bonded parts:

Bellows, boots, diaphragms, moulded part, sheets, extruded profiles, sealing caps, dampers, damping elements, grommets, protective caps, bushings, vacuum grippers, rubber-metal bonded parts, valve seats.

Testing and Consulting

We support you in your daily questions and challenges concerning components made of the fascinating material rubber. Especially during the development stage of products, it is important to know the materials used and their behaviour in the application in detail. Therefore, we test and qualify the products and materials for your application in accordance with your requirements or external specifications.

Tests following manufacturers’ specifications from different industries are as much part of our services as analyses meeting independent standards.

Furthermore, if a component no longer works, we can also help you with our experience and competence in failure analysis.

Since 2013, hoses and the relevant components have been one of the priorities in our daily work.

In order to qualify elastomer materials for hoses, testing directly at the hose is often required. Since the complete hose cannot be used for the individual material tests, it is necessary to prepare suitable test specimens from the hoses.

In our test laboratory, we have a special splitting machine to cut off single, thin layers of material from the hoses for the preparation of test specimens.

One hose for Every Medium

Hoses made of elastomer materials are used wherever gaseous or liquid substances are transported. The variety of hoses and components that we deal with in daily life is correspondingly large:

Hoses for medicine, food, water, drinking water, hot water, steam, gas, oil, mineral oil, hydraulics, pneumatics, tar & bitumen, concrete & mortar, air & compressed air, varnish and paint, hose bends, bushings, bellows, moulded tubes, spiral hoses, plug-in hoses and many more.

Testing and Consulting

Material testing is also the focus for hoses. We carry out qualification tests for you as specified by the OEM and examine the ozone resistance of the hose materials in accordance with various standards. Especially for climate hoses, we include the PA barrier layer in our tests.

Our services for hose applications at a glance

ProducingTest Specimens from Hoses

By means of a splitting machine, we remove individual 0.5-2 mm thick layers from the hose and then punch tensile test bars therefrom. A suitable splitting machine is available for this purpose in our test laboratory.

By means of a splitting machine, we remove individual 0.5-2 mm thick layers from the hose and then punch tensile test bars therefrom. A suitable splitting machine is available for this purpose in our test laboratory.

In the automotive industry, many different elastomer parts are used. They seal, dampen and store or transport media to their point of use. Seals, hoses, belts, bearings, dampers, profiles, moulded parts or valve seats are just some of the components we deal with in this context.

Hardly any other branch of industry has developed so many and extensive specifications in recent years as the automotive industry. Materials and components go through numerous testing and approval phases before they find their way into an automotive application.

Especially for the automotive industry and its suppliers, the Elastomer Institut Richter offers conformity tests in accordance with OEM specifications. For customers from the automotive industry, we test elastomers following the corresponding automotive specifications of the OEMs (Daimler, BMW, PSA, VW, Porsche…) or in accordance with company-independent standards (ECE, DIN, ISO…).

Testing and Consulting

In accordance with the requirements of car manufacturers, we test the chemical resistance of elastomers in typical automotive fluids using immersion tests with and without the exposure to temperature. These include tests in fuels or brake fluids, coolants, cooling water, oils and blow-by gases.

However, we are also at your side with our knowledge for components in modern drives. We support you in the qualification of new products and materials for the path to electromobility. Material tests, ageing tests, resistance tests and the creation of service life curves in line with Arrhenius also help to evaluate and ensure the suitability of elastomers for the operating conditions.

Specific contact and surface resistances give information about the performance of the components in the electrical environment.

With our special LNP® measuring technology, we are also able to perform mechanical tests directly on filigree finished parts, determine their hardness and draw conclusions about the degree of material cross-linking.

Overview OEM specifications as PDF download